GE Aviation said initial personnel and special processing equipment are in place at a new $200 million factory complex in Alabama that will be America’s first production center for unique materials used to manufacture ceramic matrix composites (CMCs).

CMCs are poised to revolutionize aerospace manufacturing because of their ultra-lightweight properties and their ability to withstand extremely high temperatures.

The center in Huntsville comprises two adjacent factories standing on 100 acres, where silicon carbide (SiC) materials will be mass produced. The plants are critical in enabling GE Aviation to produce CMC components in large volume.

“The equipment coming into our Huntsville factories is unique,” said Jon Lyford, plant manager for GE Aviation’s Huntsville operations.

To staff the facility, GE Aviation has been hiring engineers outside the traditional areas of aerospace engineering.

“We are hiring experts in the area of process-based manufacturing found in the oil and gas, chemical and the consumer packaged goods industries,” Lyford said.

“Managing the production of CMC materials requires a special skill set. We have several key leadership positions in place, and we begin hiring hourly workers toward the end of the year.”

GE Aviation, which announced plans for the center in 2015, expects to deliver its first CMC materials from Huntsville by mid-2018.

Growth plans

The company’s growing Huntsville team today numbers 40 employees. It anticipates about 150 employees in the plants by the end of 2018. About 300 employees are expected to run the operation at peak production.

At the Huntsville plant complex, one factory will produce SiC ceramic fiber, the raw material used to make the unidirectional CMC tape being produced in the neighboring factory. The CMC tape will be used to fabricate CMC components for jet engines and land-based gas turbines.

The fiber plant is modeled after the SiC fiber factory of NGS Advanced Fibers in Japan, a joint company of Nippon Carbon, GE and Safran of France. The expanding NGS operation is the only plant in the world today producing CMC fiber on a large scale.

Surging demand

Demand for CMCs is expected to grow tenfold over the next decade driven by rising jet engine production rates.

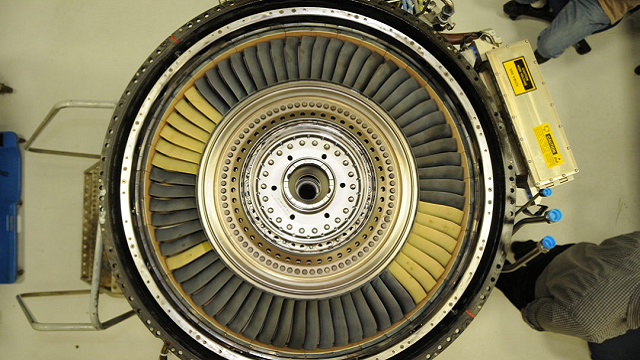

Each new LEAP engine, produced by CFM International (a joint venture between GE and Safran) has 18 CMC turbine shrouds, which are stationary parts in the high-pressure turbine that direct air and ensure turbine blade efficiency.

CFM is expected to deliver about 500 LEAP engines this year, 1,200 in 2018 and 1,800 in 2019.

The use of lightweight, heat-resistant CMCs in the hot section of GE jet engines is a breakthrough for the jet propulsion industry.

With one-third the density of metal alloys, these ultra-lightweight CMCs reduce the overall engine weight. Further, their high-temperature properties greatly enhance engine performance, durability and fuel economy.

GE Aviation also produces fuel nozzles for LEAP engines using additive manufacturing at a facility in Auburn.

This story originally appeared on the Alabama Department of Commerce’s Made in Alabama website.

Jerry Underwood for Made in Alabama | © 2017, alabamanewscenter.com